With years of experience, our companies have always believed strongly in the concept of collaborative growth and run across the broad spectrum of all business activities with diversities and demographics.

about our company

INTRODUCTION

COMPANY FOUNDER HISTORY

Early Training

Mr. Parth B Patel (Edu Msc.IT) Our company founder has started his carrier under training of his father Late Shri Bhupendrabhai N Patel (Edu B.E Metallurgy).

2011 – OM Industries

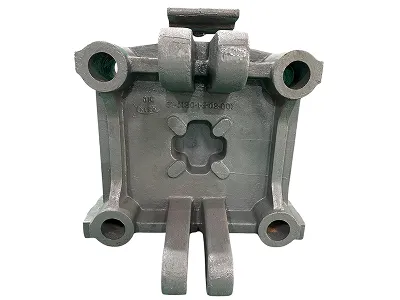

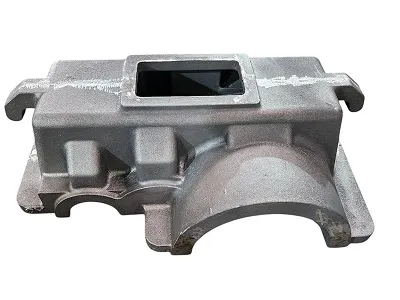

In 2011 after training he started his own company name OM Industries in 800 sq yard with production capacity of 60 tons per month working in CI & SG Graded Casting. Today Company turnover is around 8 to 10 Cr.

2015 – Styro Steel Cast Pvt Ltd

In 2015 He takeover company Styro steel Cast Pvt Ltd with starting production capacity of 40 tone per month worked in Alloy Steel and Mn Steel Casting.Now company is producing 130 tone per month working in Mn Steel ,Alloy Steel,Hi- crome , Ni-Hard ,En Series.Today Company turnover is around 18 to 20 cr.

2024 – OM Inductocast

In 2024 He started our new company OM Inductocast with production capacity of 300 tons per month and have target to achieve 45 to 50 cr turnover in next 3 years.